A bioinspired hydrogel that behaves more like natural cartilage could ease osteoarthritis

The world’s population is trending older – in large part because we take better care of ourselves, such as through exercise. But those years of running, playing, even just of everyday living, take a toll on our joints, often leading to osteoarthritis.

Age is only one risk factor for osteoarthritis, which predominantly occurs in the knees, hips, and hands. Other factors include joint injury or overuse/repetitive stress, such as from running and other sports; gender, with women (of course) being more likely to develop the disease; weight; and genetics.

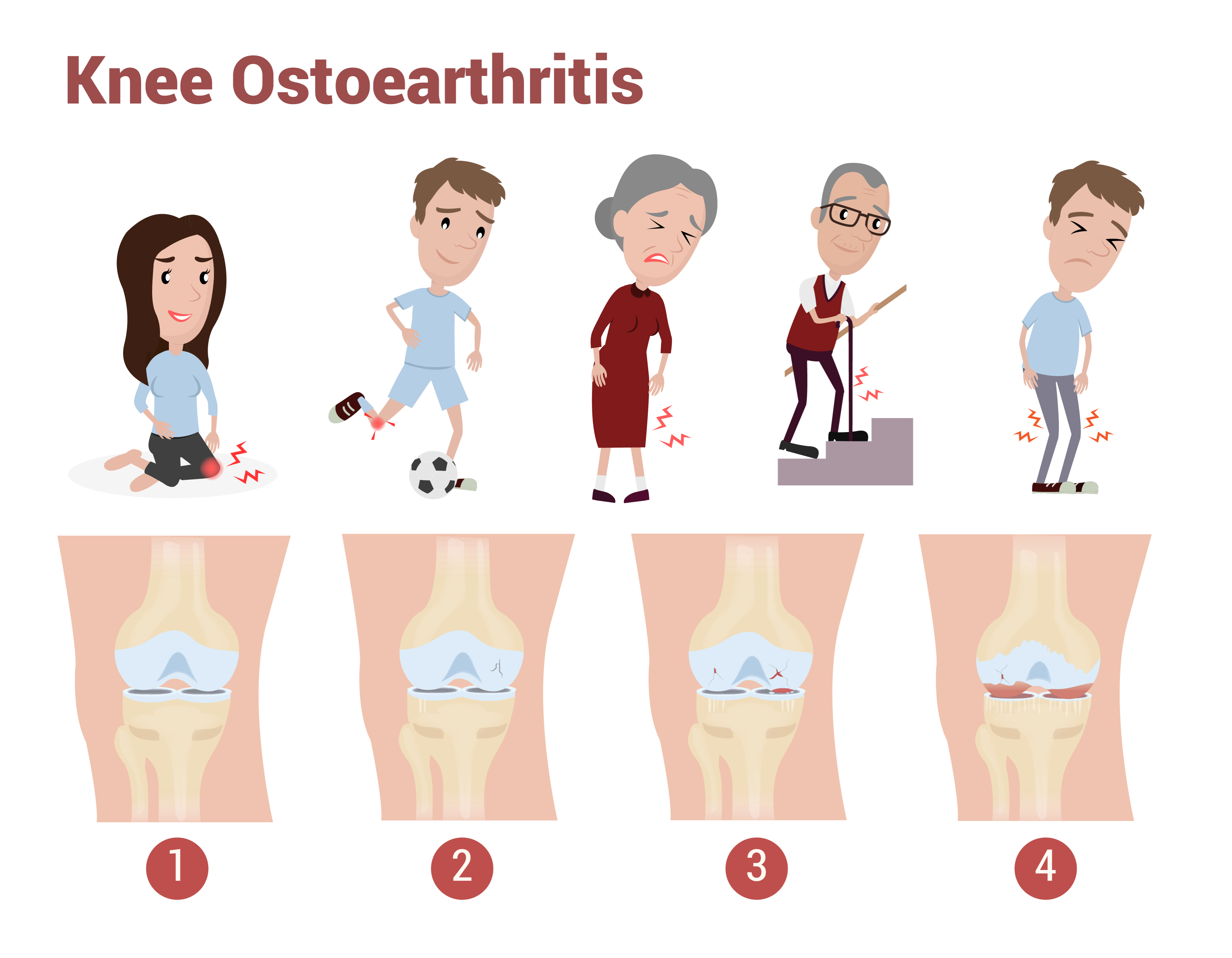

Osteoarthritis is the most common form of arthritis, afflicting 32.5 million Americans. But what, exactly, is it? “The cartilage within a joint begins to break down and the underlying bone begins to change. These changes usually develop slowly and get worse over time,” says the CDC. Osteoarthritis “can cause pain, stiffness, and swelling. In some cases it also causes reduced function and disability; some people are no longer able to do daily tasks or work.”

Treatments for this “wear and tear” condition range from icing the joint to total replacements, but for many sufferers – including The Curiosity Review – none of the options are ideal. That’s why we felt anticipatory relief just reading about a new Weizmann Institute breakthrough: a bioinspired hydrogel that could ease the pain of osteoarthritis.

For about 20 years, Prof. Jacob Klein has sought to truly understand cartilage and its unique, superior properties; for example, the outermost layer of cartilage in our joints has a lower friction coefficient than any human-made material. By learning what makes cartilage so durable and effective and by gaining insight into the lubricating properties that help our bones glide so smoothly, Klein and his colleagues also hope to learn how to alleviate the effects of its wear and tear.

The team made a major advance in that direction with the discovery that the lubricating effects are based on lipids. These fatty molecules bind tightly to the cartilage surface, making it resilient under pressure but keeping it well lubricated with a thin, friction-reducing fluid layer that enables the bones in our joints to slide, swivel, and pivot for (hopefully) years on end.

The Klein group used this finding to create a new type of hydrogel. While hydrogels are already widely used for a number of biomedical purposes, including contact lenses and achy joints, they are not a cure-all; e.g., up to 40% of people given hydrogel injections still have reduced function and are still in pain.

Remarkably, the new hydrogels performed up to 100 times better at reducing friction and wear than regular hydrogels. The team inserted “microreservoirs” of lipids into the gels, similar to what occurs in nature; when there is friction on the surface of the gel, the lipids are released, thus providing lubrication on an ongoing basis. “As the friction and wear take off a bit of the gel surface – mere microns at a time – new lipid lubricants get exposed. That way, the lubrication at the surface is continually renewed,” Klein explains.

The gels have another beneficial trait: if they dry out, they can be rewetted without harming their lubrication abilities – a property that could give them long shelf life and that suggests innovative new uses.

This work could, in the near future, lead to the development of artificial joints that can better withstand wear and tear – meaning that replacement joints can last longer and cause fewer problems. A gel with better lubricating properties could also have applications in uses such as stent insertion and tissue engineering.

In 2019, some of the Klein team established a startup called Liposphere in order to advance such applications. The woman-led firm is getting attention: In 2020, Nature and Merck named it “one of the 44 most exciting, science-based firms spun out from academic environments” worldwide.

We wish the hydrogel success and speedy travel from the lab to the marketplace – where we will be waiting.